MANUFACTURING

Each wheel goes through the entire production process and is treated with care.

Engineering | Forging | Milling | Finishing | Packaging

Behind every wheel lies a story of craftsmanship and care. 🔧✨

At Splux, each wheel is meticulously crafted from start to finish, reflecting our commitment to exceptional quality and service. Want to dive into our manufacturing process? Keep reading!

ENGINEERING

Order Confirmation and Customization

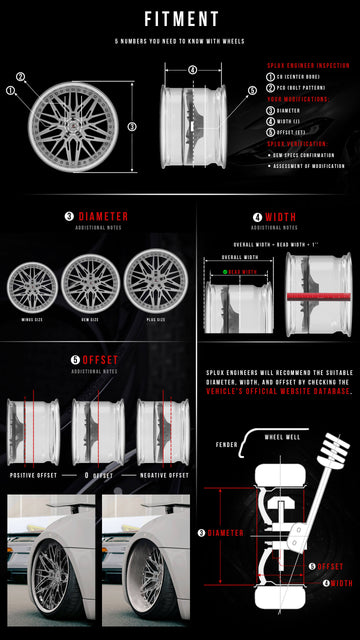

Once you place an order, our professional engineering team immediately gets to work, fully understanding your vehicle and wheel customization details. From the car model and trim to modification needs, we meticulously verify every detail. We measure the center bore, PCD, wheel size, and design, and ultimately determine the wheel offset (ET). Only one-on-one customization can achieve the perfect fitment. Our goal is to ensure each wheel not only fits perfectly but also surpasses OEM wheels in performance and appearance.

Rendering Design Drawings and Engineering Files

Next, our engineers use professional software like AutoCAD and Siemens NX to generate precise 2D and 3D design files. We conduct rigorous tests through finite element analysis (FEA) to ensure the strength and durability of the wheels in real-world use. Every line and curve is meticulously designed and validated to create the most exceptional products.

Machining Programming

Once the design is approved, our engineers perform precise lathe and milling programming, allowing our precision equipment to process the production according to the design drawings. Every detail is accurately replicated to ensure the final product matches the design perfectly. Rest assured, every product meets the highest standards of precision and quality.

FORGING

Raw Material

We use the industry's highest quality 6061 aluminum, sharing a production line with aerospace manufacturing. Using the most advanced German Leifeld spinning machine, the aluminum is pressed with 12,000 tons of pressure, then undergoes T6 heat treatment. Depending on the wheel design and size, our engineers select the most suitable forgings from hundreds of different shapes and specifications. For example, a 20-inch forging can weigh up to 126 pounds.

Lathe Turning

In this step, approximately 50% of the material is removed through high-precision lathe machining, forming the preliminary contour of the wheel in about one hour. Our equipment and technical team ensure that every wheel meets the expected precision and quality.

First QC

After machining, we immediately measure the center bore to ensure accuracy. We firmly believe that the sooner an issue is detected, the better. We always go the extra mile for precision.

MILLING

CNC Milling

Next, our high-end Japanese CNC milling machines come into play. Equipped with a range of precision cutting tools, they perfectly render sharp and intricate spoke designs. A 20-inch wheel with a complex spoke structure might have 30 pounds of material removed, with each detail meticulously brought to life over hours of continuous machining. It's not just about stunning design; our high-end CNC mills also ensure product durability by guaranteeing roundness. You’ll be amazed by our commitment to precision and detail.

Back Pocketing

Our engineers remove excess material from the back of the wheel, reducing weight by an additional 1-3 pounds while maintaining strength and durability. Each wheel finds the perfect balance between lightweight and strength.

Second QC - Runout Check

With the machining complete, we proceed to the second QC, including runout and dynamic balance tests.

FINISHING

Cleaning

Before achieving a flawless finish, we first ensure the wheel is impeccably clean. Each wheel undergoes thorough cleaning with gentle alkaline cleaners to remove grease, solvents, and residues, followed by pure water rinsing to eliminate all oils and dust particles. This step is crucial as surface preparation directly impacts the adhesion of the coating powder and the quality of the final finish.

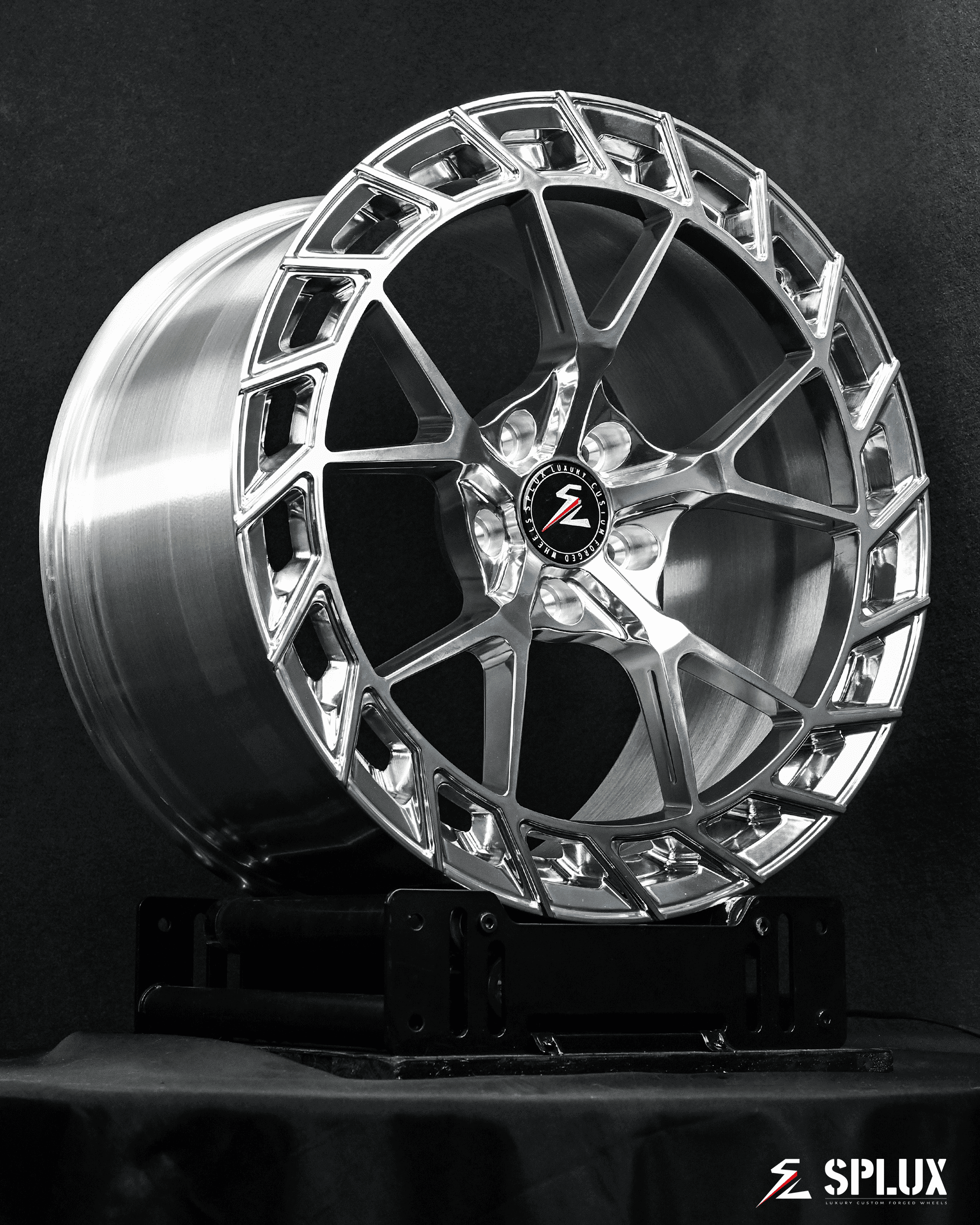

Hand Polishing

If you opt for a polished finish, our craftsmen use wool polishing wheels to hand polish each wheel, ensuring every detail is refined. They then use machines with ceramic beads to achieve an unprecedented shine and texture. This craftsmanship is not just a skill but an art.

Hand Brushing

Brushed textures add depth and character to the wheels. Our hand-brushed finishes are crafted entirely by hand, a task only seasoned artisans can handle. They meticulously brush the wheel surface, often taking two days of patience to create a perfect brushed finish. Every detail reflects the artisans' exquisite craftsmanship.

Powder Coating and Curing

Before coating, we mask areas like lug holes. Each wheel undergoes three layers of spraying and baking over at least three days to achieve a detailed and delicate color. First, a primer coat is applied to enhance surface smoothness and adhesion. The second layer adds the desired color. Finally, a clear or matte protective layer is sprayed. Each layer is cured at up to 650 degrees. We use the highest quality powders and the most stringent coating processes, offering hundreds of color options to meet all customization needs. Whether it's classic single colors or complex multi-colors, we’ve got you covered.

Traceability

Each wheel is laser-engraved with traceability information on the inner rim, allowing you to understand the production journey and unique identity of every wheel.

Assembly and Third QC - Runout Check

For 2-piece and 3-piece wheels, assembly and the third QC take place here. Using a runout gauge, our wheels achieve a deviation of less than 0.01"/0.30mm, far surpassing industry standards. This value is crucial for minimizing vehicle vibration, extending tire and wheel life, and reducing energy consumption.

PACKAGING

Final QC

Before packaging, we conduct a final quality check. Every wheel undergoes strict inspection to ensure it meets our high standards. We know that only the most perfect products will reach your hands.

Packaging

We use specialized packaging materials and methods to ensure the wheels are not damaged during transportation. Each wheel is carefully packaged, delivered to you with our promise and pride.